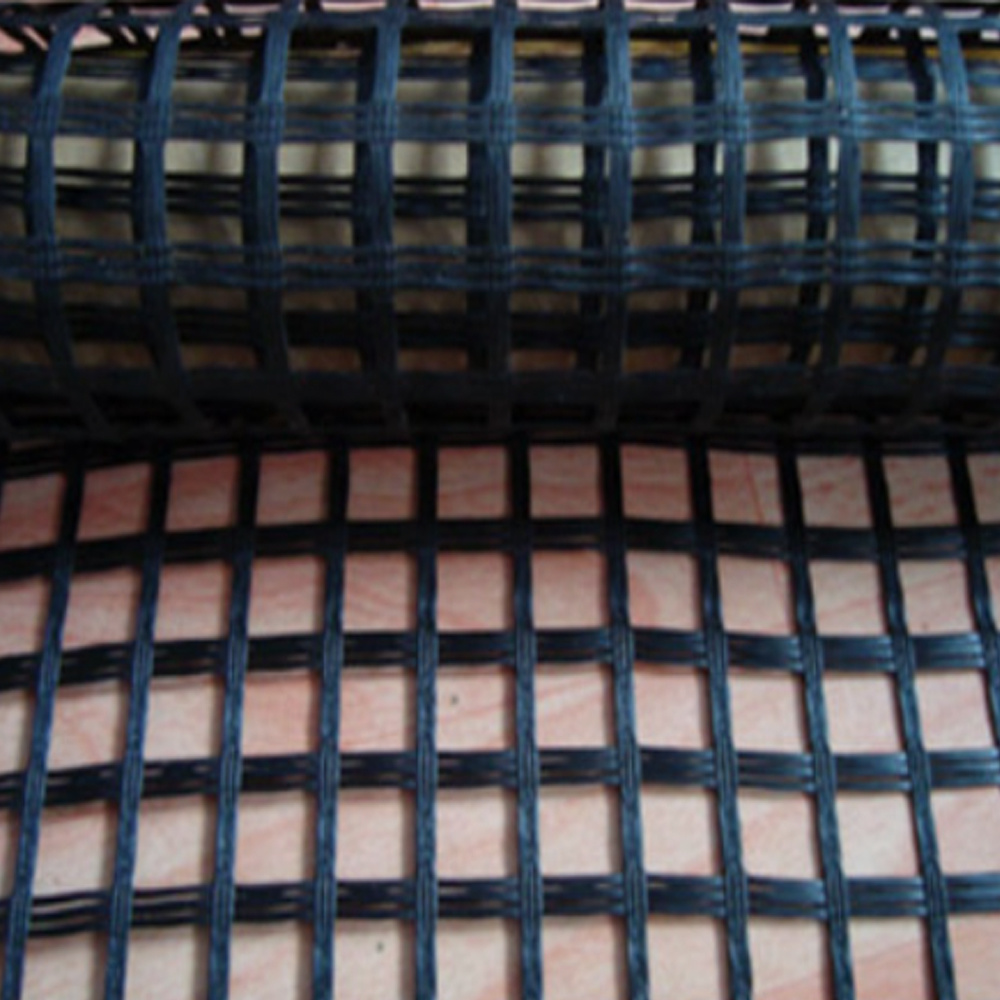

The production process of polyester geogrid

Release time:

2024-01-29

The production process of polyester geogrids generally includes the following steps:

1. Raw material preparation: Prepare polyester materials, reinforcing fibers, and other auxiliary materials such as titanium dioxide, stabilizers, etc.

2. Melt extrusion: Heat the polyester material to a molten state, and use an extruder to extrude the molten polyester material into a flat or mesh like geogrid.

3. Fiber reinforcement: Reinforcing fibers (usually glass fibers or polyester fibers) are stacked together with extruded polyester sheets to form a reinforced polyester geogrid, which is bonded together using adhesives or hot pressing methods.

|

|

|

|

4. Cooling and solidification: By adjusting the cooling method and time, the polyester geogrid is cooled and solidified to ensure it has sufficient strength and stability.

5. Cutting and processing: Cut and process the polyester geogrid as needed to form appropriate dimensions and structures for subsequent construction and installation.

6. Quality testing: Conduct quality testing on the produced polyester geogrid, including physical performance testing, size testing, aging resistance testing, etc., to ensure that the product meets relevant standards and requirements.

7. Packaging and storage: The produced polyester geogrid is packaged, usually in rolls or folds, and then labeled and stored for sale at the factory.

The above is the basic production process of polyester geogrids, and the specific production process and steps may vary depending on different manufacturers and products.