Hydraulic construction geomembrane

Classification :

keyword:

Geomembrane

PRODUCT DETAILS

Hydraulic construction geomembrane

| Name; geomembrane |

| Length; 1-6m |

| Thickness; 0.3 -2 mm |

| Material; HDPE, LDPE, PVC, LLDPE |

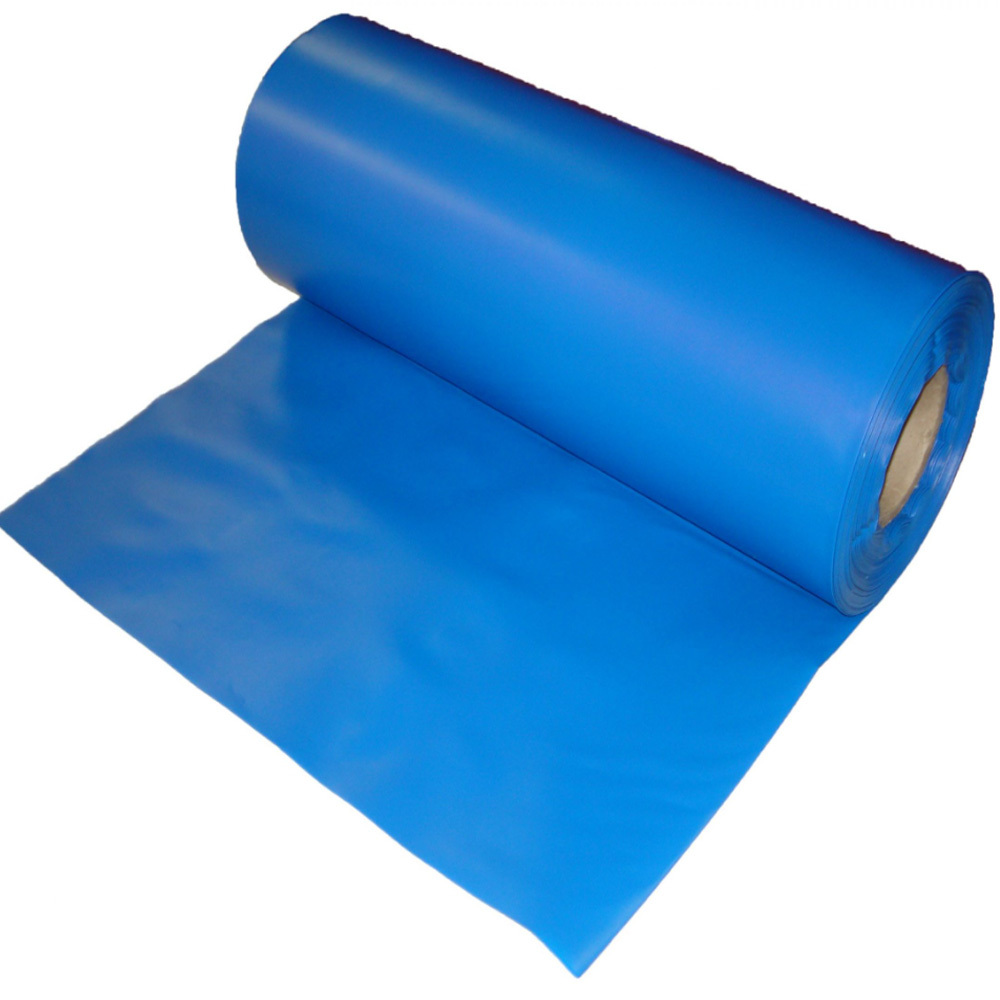

| Color; Black, white, blue, customized products can be supported according to customer needs |

Introduction

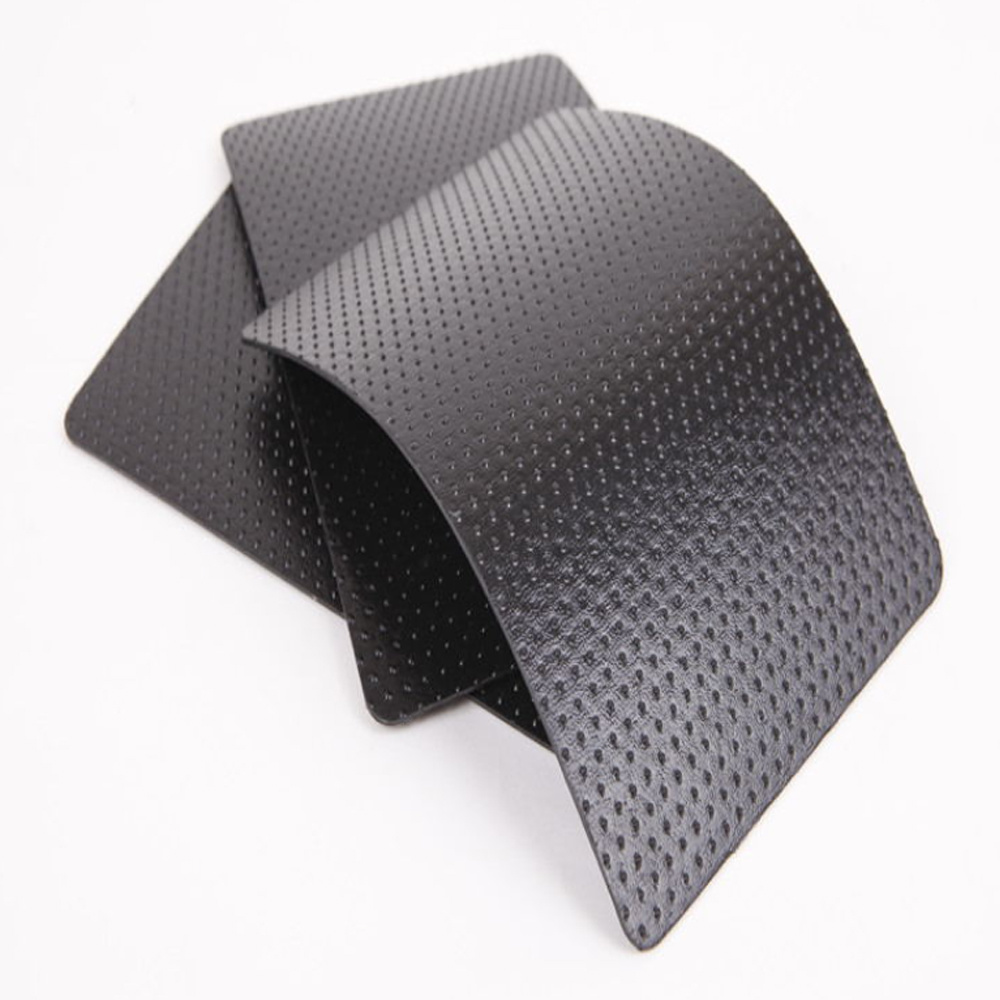

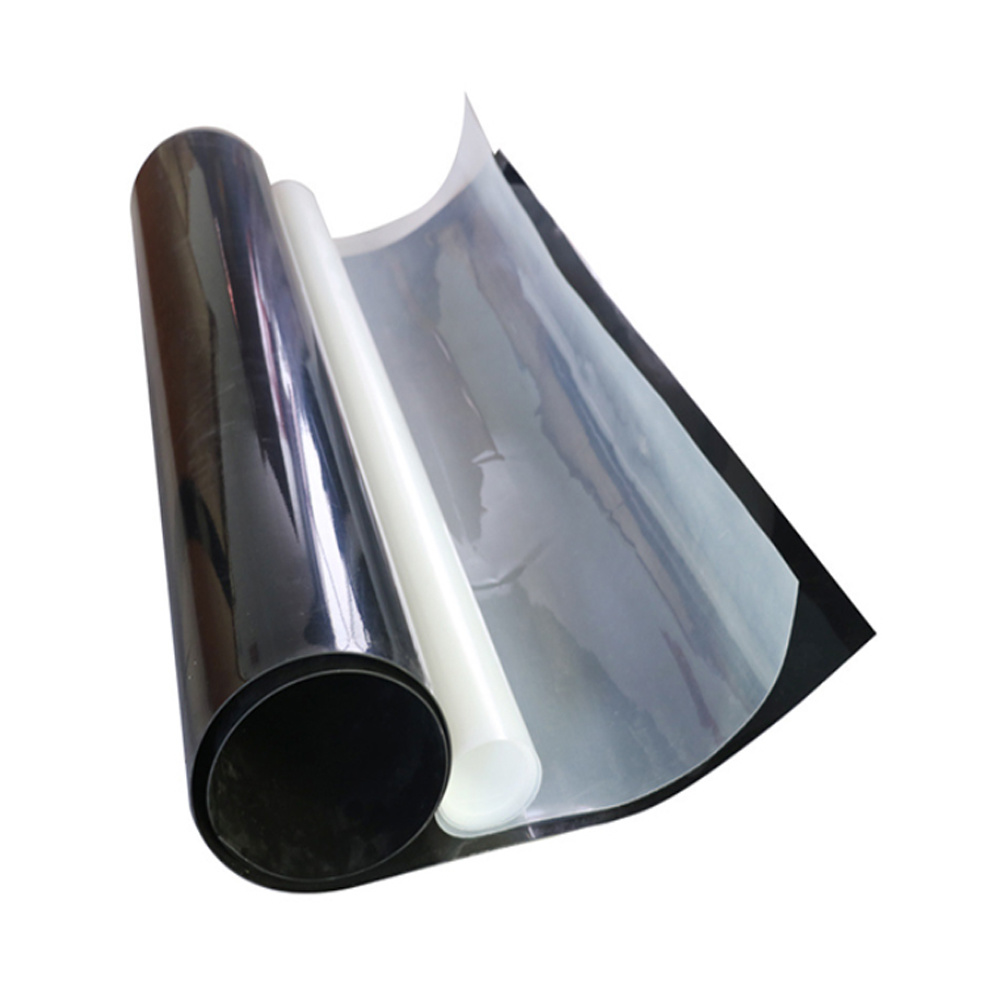

Geomembranes use plastic films as anti-seepage substrates, mainly including polyvinyl chloride (PVC) and polyethylene (PE), EVA (ethylene/vinyl acetate copolymer). In tunnel applications, ECB (ethylene vinyl acetate modified asphalt blend geomembrane) is also designed and used. They are high molecular weight chemical flexible materials with small specific gravity, strong extensibility, high adaptability to deformation, corrosion resistance, low temperature resistance, and good frost resistance.

|

|

|

|

|

Characteristic

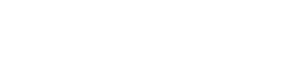

High tensile strength, low elongation, uniform longitudinal and transverse deformation, high tear resistance, excellent wear resistance, and strong water resistance.

|

|

|

|

|

Product customization

Supports color, length, width, and material (packaging shape supports customization)

|

|

|

|

|

Specifications

|

Properties |

Test Method |

GMSH050 |

GMSH075 |

GMSH100 |

GMSH150 |

GMSH200 |

|

■ Thickness |

ASTM D5199 |

0.50 mm |

0.75 mm |

1.00 mm |

1.50 mm |

2.00 mm |

|

■ Density |

ASTM D1505 |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

|

Tensile Properties |

|

|

|

|

|

|

|

■ Yield strength ■ Break strength ■ Yield elongation ■ Break elongation |

ASTM D6693 Type IV

|

7 kN/m 13 kN/m 12% 700% |

11 kN/m 20 kN/m 12% 700% |

15 kN/m 27 kN/m 12% 700% |

22 kN/m 40 kN/m 12% 700% |

29 kN/m 53 kN/m 12% 700% |

|

■ Tear Resistance |

ASTM D1004 |

62 N |

93 N |

125 N |

187 N |

249 N |

|

■ Puncture Resistance |

ASTM D4833 |

160 N |

240 N |

320 N |

480 N |

640 N |

|

■ Stress Crack Resistance |

ASTM D5397 |

500 hrs |

500 hrs |

500 hrs |

500 hrs |

500 hrs |

|

■ Carbon Black Content |

ASTM D1603 |

2.0% |

2.0% |

2.0% |

2.0% |

2.0% |

|

■ Carbon Black Dispersion |

ASTM D5596 |

For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 |

||||

|

■ Oxidative Induction Time (OIT) |

ASTM D3895 |

100 min. |

100 min. |

100 min. |

100 min. |

100 min. |

|

■ UV Resistance High Pressure OIT retained after 1600hrs |

ASTM D5885 |

50% |

50% |

50% |

50% |

50% |

|

Dimensions |

|

|

|

|

|

|

|

■ Roll Width (m) |

|

7 |

7 |

7 |

7 |

7 |

|

■ Roll Length (m) |

|

420 |

280 |

210 |

140 |

105 |

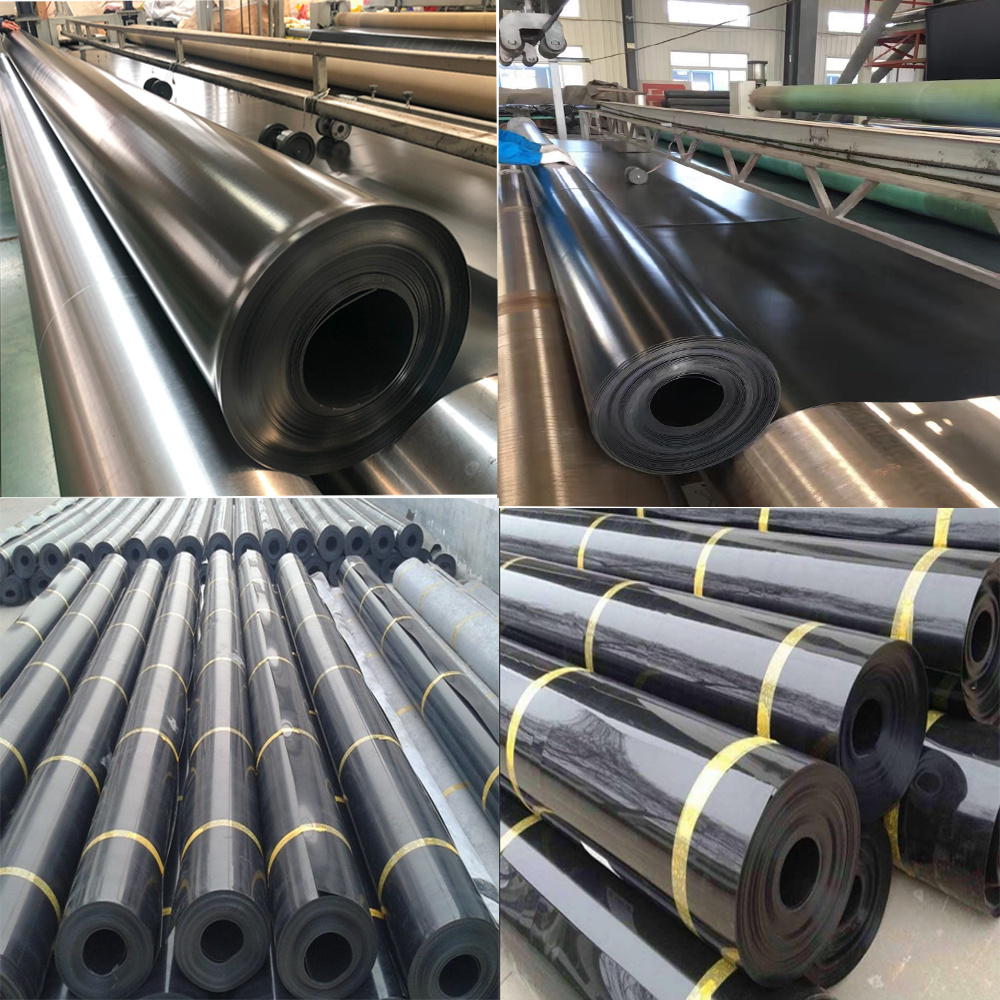

Factory strength

|

|

Applications

Applied to the projects of Landfill site, bank, dam, storage reservoir, channel, irrigation, highway, railway, tunnel, drinking tank, salt field bittern pan, chemical liquid storage, treatment tank, artificial lake and riverway etc.

Factory Appearance

RELATED PRODUCTS

GET A FREE QUOTE