Retaining Wall Plastic Uniaxial Geogrid For Slop Stabilization Hdpe Material

Classification :

keyword:

PP/HDPE Uniaxial Geogrid

PRODUCT DETAILS

| Product name; One way plastic geogrid |

| Material; Polypropylene (PP) Polyethylene (HDPE) |

| Width; 1-4m |

The landfill assignment employs PP/HDPE Uniaxial Geogrid to decorate the balance and overall performance of the landfill structure. This geogrid is made of exquisite polypropylene and high-density polyethylene materials, making sure sturdiness and long-lasting strength. The uniaxial diagram offers amazing reinforcement in one direction, efficaciously distributing the load and stopping soil erosion. By incorporating this geogrid into the landfill construction, the average balance and overall performance of the shape are considerably improved, lowering the chance of slope failure and improving the average toughness of the landfill. The use of PP/HDPE Uniaxial Geogrid is a competitively priced and dependable answer for maximizing the effectivity and sustainability of landfill projects.

PP/HDPE uniaxial geogrids are broadly used in landfill tasks for more than a few functions due to their top of the line overall performance and sturdiness in contrast to common materials. These geogrids are made from exceptional polypropylene or high-density polyethylene, imparting first-rate tensile electricity and resistance to chemical and organic degradation.

One of the key purposes of PP/HDPE uniaxial geogrids in landfill initiatives is in slope stabilization. Landfills frequently have steep slopes that are susceptible to erosion and instability. By putting in these geogrids, the soil is strengthened and confined, stopping soil motion and erosion. This helps to hold the integrity of the landfill shape and stop soil contamination.

Furthermore, PP/HDPE uniaxial geogrids are normally used in landfill capping systems. Landfill caps are imperative for stopping water infiltration and fuel emissions from the waste material. The geogrids act as a barrier to water movement, imparting a steady base for the placement of the landfill cowl materials. This ensures the long-term overall performance of the landfill cap and minimizes the chance of environmental contamination.

In addition, PP/HDPE uniaxial geogrids are additionally used in landfill get admission to roads and working platforms. These geogrids supply reinforcement to the soil, enhancing its load-bearing ability and lowering the threat of rutting and deformation. This ensures protected and steady get right of entry to for heavy gear and vehicles, facilitating environment friendly operation and upkeep of the landfill site.

Overall, the software scope of PP/HDPE uniaxial geogrids in landfill tasks is extensive, ranging from slope stabilization and capping structures to get right of entry to roads and working platforms. Their optimum overall performance and sturdiness make them a economical and dependable answer for making sure the long-term balance and environmental safety of landfill sites.

|

Spec Item |

TGDG35 |

TGDG50 |

TGDG80 |

TGDG90 |

TGDG110 |

TGDG130 |

TGDG160 |

|

Width (m) |

1~3 |

1~3 |

1~3 |

1~3 |

1~3 |

1~3 |

1~3 |

|

Tensile strength≧(Kn/m) |

35 |

50 |

80 |

90 |

110 |

130 |

160 |

|

Nominal Elongation ≦(%) |

11.5 |

11.5 |

11.5 |

11.5 |

11.5 |

11.5 |

11.5 |

|

Tensile strength at 2% strain ≧(Kn/m) |

7.5 |

12 |

21 |

23.7 |

29.9 |

38 |

47 |

|

Tensile strength at 5% strain ≧(Kn/m) |

21.5 |

23 |

40 |

45.2 |

56.5 |

75.5 |

93 |

|

Item Spec |

TGDG50 |

TGDG80 |

TGDG110 |

TGDG120 |

TGDG160 |

TGDG200 |

TGDG260 |

|

Width |

1~3 |

1~3 |

1~3 |

1~3 |

1~3 |

1~3 |

1~3 |

|

Tensile strength ≥(KN/m) |

50 |

80 |

110 |

120 |

160 |

200 |

260 |

|

Nominal Elongation ≤(%) |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

|

Tensile strength at 2% strain ≥(KN/m) |

12 |

26 |

32 |

36 |

45 |

56 |

94 |

|

Tensile strength at 5% strain≥(KN/m) |

28 |

48 |

64 |

72 |

90 |

112 |

185 |

|

|

Q: What can you buy from us?

A: Geomembrane,Geogrid,Geocell, Geotextile, Geocomposite,

Q: Can I have a sample?

A: Yes. And sample free.

Q: What's the payment terms?

A: T/T or L/C. Others could be negotiated.

Q: What's the delivery time?

A: 3-20 days after confirming order, detail delivery date should be decided according to production season and order quantity.

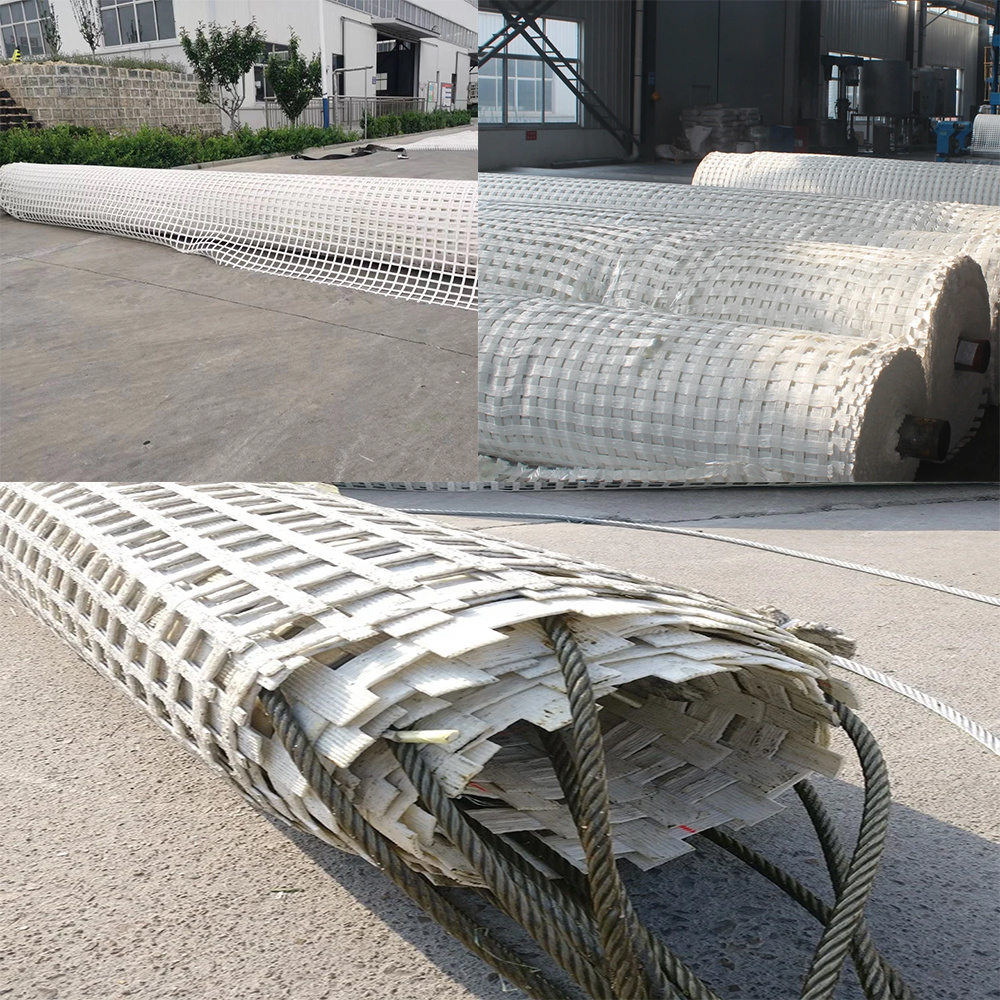

Factory Appearance

RELATED PRODUCTS

GET A FREE QUOTE