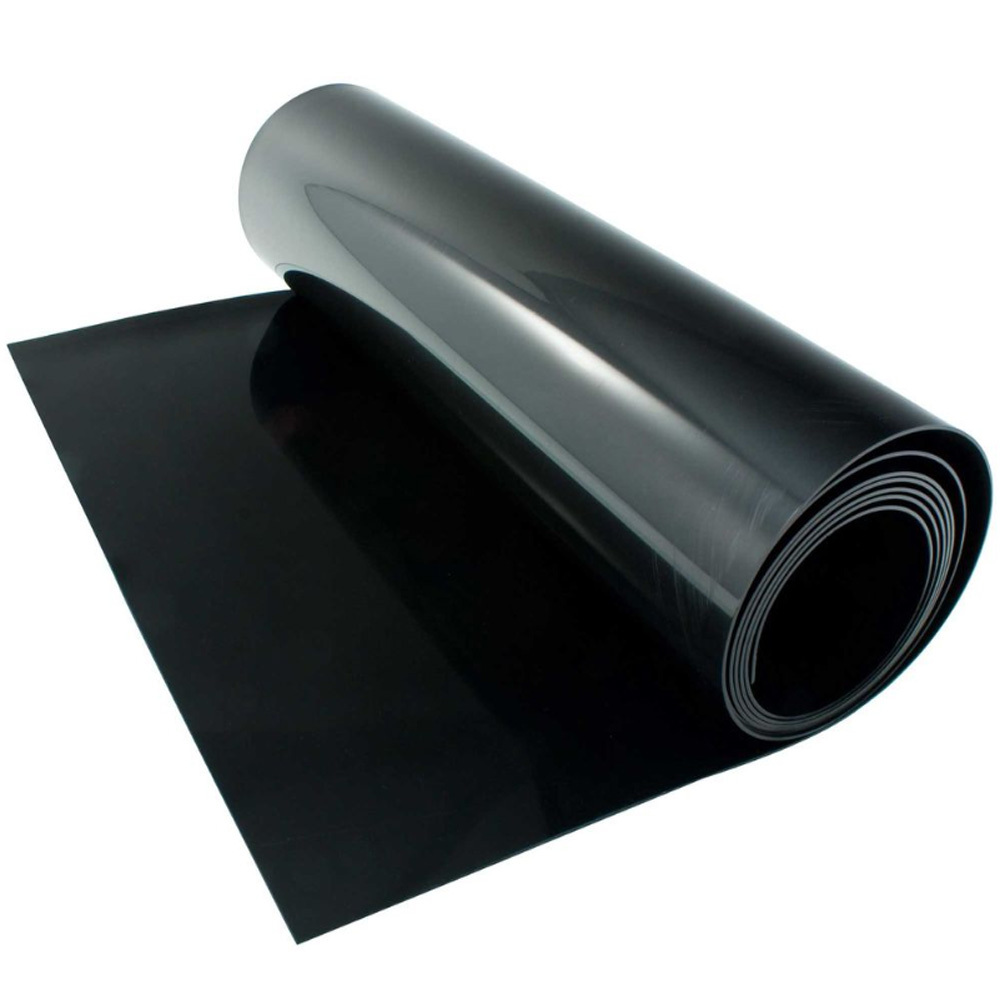

Garden reservoir HDPE Geomembrane

Classification :

keyword:

Geomembrane

PRODUCT DETAILS

Garden reservoir HDPE Geomembrane

Introduction

Smooth HDPE Geomembrane is manufactured from High Density Polyethylene resin with proportional carbon black antioxidant, anti-aging and UV-resistance substances by using the science of coextrusion-blown triple layer. The surfaces of each facets are smooth,Geomembrane is a geoimpermeable fabric made of plastic movie as impermeable substrate. It is a water-resistant constructing cloth which is impermeable and moisture-proof. Its impermeable property primarily relies upon on the impermeable property of plastic film.

Geomembrane materials and characteristics The main feature of geomembrane;

Is very low water permeability, so the basic materials for the manufacture of geomembrane are mainly polymers with low water permeability, asphalt and synthetic fibers and fabrics, in addition, there are certain fillers and admixtures. Such as: polyvinyl chloride (PVC) chlorinated polyethylene (CPE) high, medium and low density polyethylene (HDPE, MDPE, LDPE) plastics; Butyl rubber (IIR) propylene oxide rubber (ECO) Neoprene rubber (CR) rubber; Ethylene propylene (EPDM) ethylene vinyl acetate (EVA) mixed class. Admixtures include plasticizers, anti-aging agents, antibacterial agents, various stabilizers and so on.

Specifications

|

Properties |

Test Method |

GMSH050 |

GMSH075 |

GMSH100 |

GMSH150 |

GMSH200 |

|

■ Thickness |

ASTM D5199 |

0.50 mm |

0.75 mm |

1.00 mm |

1.50 mm |

2.00 mm |

|

■ Density |

ASTM D1505 |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

0.940 g/cc |

|

Tensile Properties |

|

|

|

|

|

|

|

■ Yield strength ■ Break strength ■ Yield elongation ■ Break elongation |

ASTM D6693 Type IV

|

7 kN/m 13 kN/m 12% 700% |

11 kN/m 20 kN/m 12% 700% |

15 kN/m 27 kN/m 12% 700% |

22 kN/m 40 kN/m 12% 700% |

29 kN/m 53 kN/m 12% 700% |

|

■ Tear Resistance |

ASTM D1004 |

62 N |

93 N |

125 N |

187 N |

249 N |

|

■ Puncture Resistance |

ASTM D4833 |

160 N |

240 N |

320 N |

480 N |

640 N |

|

■ Stress Crack Resistance |

ASTM D5397 |

500 hrs |

500 hrs |

500 hrs |

500 hrs |

500 hrs |

|

■ Carbon Black Content |

ASTM D1603 |

2.0% |

2.0% |

2.0% |

2.0% |

2.0% |

|

■ Carbon Black Dispersion |

ASTM D5596 |

For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 |

||||

|

■ Oxidative Induction Time (OIT) |

ASTM D3895 |

100 min. |

100 min. |

100 min. |

100 min. |

100 min. |

|

■ UV Resistance High Pressure OIT retained after 1600hrs |

ASTM D5885 |

50% |

50% |

50% |

50% |

50% |

|

Dimensions |

|

|

|

|

|

|

|

■ Roll Width (m) |

|

7 |

7 |

7 |

7 |

7 |

|

■ Roll Length (m) |

|

420 |

280 |

210 |

140 |

105 |

Applications

Applied to the projects of Landfill site, bank, dam, storage reservoir, channel, irrigation, highway, railway, tunnel, drinking tank, salt field bittern pan, chemical liquid storage, treatment tank, artificial lake and riverway etc.

Factory Appearance

RELATED PRODUCTS

GET A FREE QUOTE