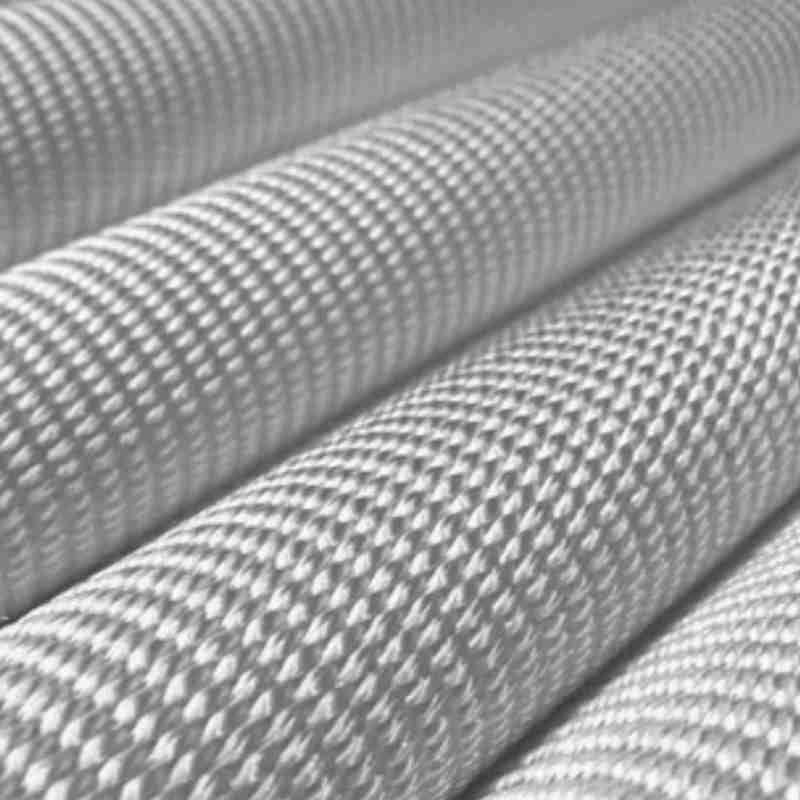

Pet High Strength Filament Woven Geotextile for Roadbed Construction

Classification :

keyword:

Woven geotextile

PRODUCT DETAILS

| Product specification |

| Name; woven geotextiles |

| Thickness; 100g-800g |

| Length; 1-6 meters, if there is a unique measurement can be customized |

| Color; White, black, aid customized hues |

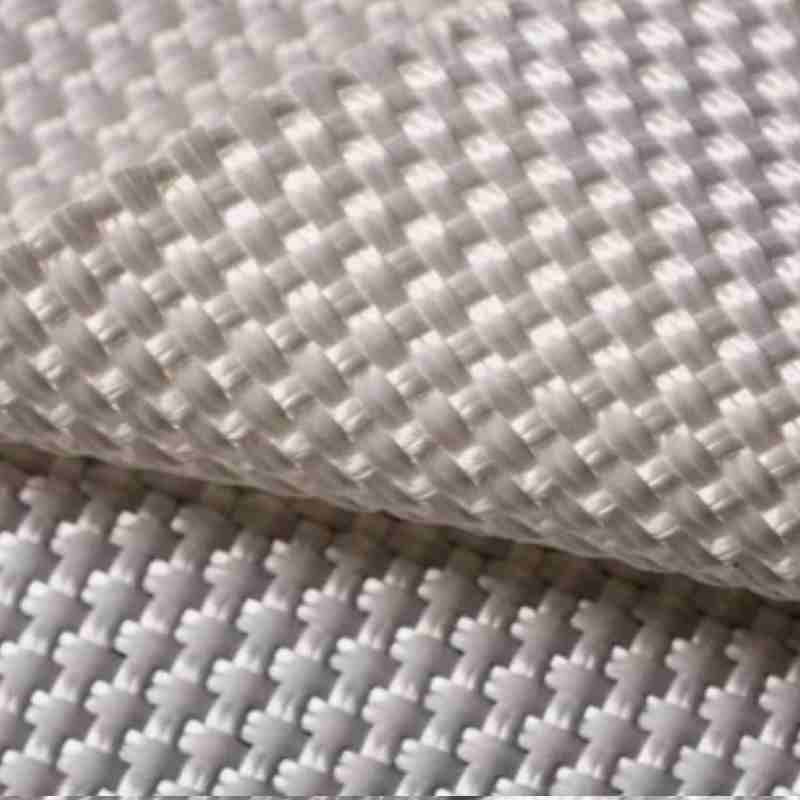

Pet woven geotextile, also known as polyester woven geotextile, is a type of geotextile made from high-quality polyester fibers. These fibers are tightly woven together to create a durable and strong material that is ideal for a variety of civil engineering and construction applications.

One of the key advantages of pet woven geotextile is its high tensile strength. This means that it can withstand significant loads and stresses without breaking or tearing, making it an excellent choice for reinforcing soil and preventing erosion. In addition, the woven construction of the geotextile provides excellent dimensional stability, ensuring that it maintains its shape and integrity over time.

Pet woven geotextile is also highly resistant to UV radiation, chemicals, and biological degradation, making it suitable for use in a wide range of environmental conditions. This makes it a versatile and long-lasting solution for applications such as road construction, slope stabilization, and drainage systems.

In addition to its strength and durability, pet woven geotextile is also easy to install and can be customized to meet the specific requirements of a project. It can be easily cut and shaped to fit the contours of the land, and can be installed using a variety of methods, including anchoring, trenching, and sewing.

Overall, pet woven geotextile is a reliable and cost-effective solution for a wide range of civil engineering and construction projects. Its combination of strength, durability, and versatility makes it a popular choice among engineers and contractors looking for a high-quality geotextile solution. Whether you are working on a small landscaping project or a large-scale infrastructure development, pet woven geotextile is a reliable and effective option for reinforcing soil, preventing erosion, and ensuring the long-term stability of your project.

|

|

|

|

|

Pet woven geotextile is a versatile material that finds applications in various construction projects. Its primary function is to provide reinforcement and stabilization to soils, preventing erosion and promoting better load distribution.

One common application of pet woven geotextile is in road construction. It is used as a robust separator between the subgrade and base course layers, preventing the mixing of different materials and ensuring proper drainage. This helps in extending the lifespan of the road and reducing maintenance costs.

In addition, pet woven geotextile is also widely used in soil stabilization projects. By adding a layer of geotextile to the soil, it helps in improving the overall strength and durability of the ground. This is particularly useful in areas prone to erosion or landslides, as the geotextile can help in preventing soil movement and maintaining slope stability.

Moreover, pet woven geotextile is commonly used in landscaping projects. It can be used to create retaining walls, reinforce embankments, and provide structural support to vegetated slopes. The geotextile acts as a barrier, preventing the loss of soil and ensuring the stability of the landscape.

In the field of agriculture, pet woven geotextile is used to improve the quality of soil and enhance crop growth. By laying down geotextile fabric, farmers can protect their crops from erosion, reduce weed growth, and promote better water retention in the soil. This ultimately leads to higher yields and better overall agricultural productivity.

Overall, pet woven geotextile is a valuable material with a wide range of applications in construction, landscaping, and agriculture. Its ability to provide reinforcement and stabilization to soils makes it an essential component in various projects, helping to ensure the longevity and stability of structures and landscapes.

| project | unit | Testing standards | Technical parameters | ||||||||||||

| HK270 | HK370 | HK570 | HK380 /(a) | HK380B | HK580/(a) | HK580B | HK380PPi | HK380PPi-B | HK580PPi | HK580PPi-B | HKH2Oi | ||||

| Breaking strength | Meridian | KN/m | ISO 10319-2015 | 50 | 50 | 70 | 70 | 70 | 90 | 90 | 70 | 70 | 90 | 90 | 90 |

| zonal | 50 | 65 | 70 | 60 | 50 | 80 | 85 | 80 | 90 | 105 | 105 | 90 | |||

| Elongation at break | Meridian | % | ISO 10319-2015 | 10 | 10 | 10.5 | 10 | 10.5 | 10 | 10 | 13 | 13 | 14 | 14 | 13 |

| zonal | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 9 | 9 | 9 | 9 | 9 | |||

| Breaking strength at elongation 2% | Meridian | KN/m | ISO 10319-2015 | 13 | 13 | 15 | 15 | 15 | 18 | 18 | 10.5 | 9.5 | 8 | 7 | 9 |

| Breaking strength at elongation5% | Meridian | KN/m | ISO 10319-2015 | 30 | 30 | 38 | 38 | 38 | 45 | 45 | 30.6 | 25 | 22 | 25 | 28 |

| Mass per unit | g/m2 | GB/T13762-1992 | 225 | 250 | 310 | 280 | 260 | 375 | 380 | 340 | 345 | 420 | 435 | 430 | |

| Static breaking strength(CBR) | KN | GB/T 14800-2010 | 6 | 6.5 | 8 | 8 | 7 | 9 | 10 | 9 | 9 | 10 | 10 | 11 | |

| Equivalent aperture(O90) | mm | GB/T 14799-2005 | 0.42 | 0.45 | 0.48 | 0.48 | 0.33 | 0.45 | 0.4 | 0.48 | 0.48 | 0.47 | 0.48 | 0.45 | |

| permeability(Q50) | L/m2/s | GB/T 15789-2005 | 33 | 28 | 57 | 55 | 54 | 45 | 42 | 58 | 59 | 58 | 52 | 18 | |

| UV resistance(500 hour strong preservation rate) | % | ASTM D4355-2014 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | / | |

|

|

|

|

|

|

|

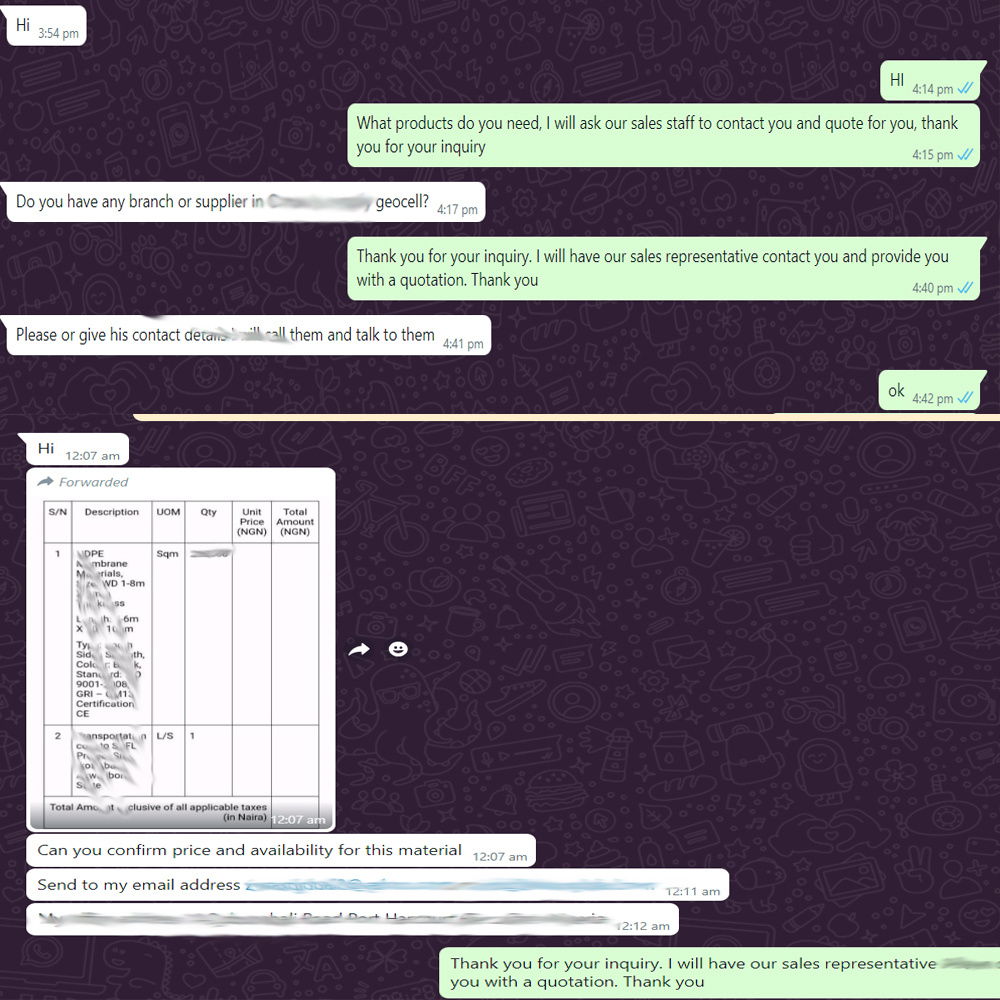

Q: What can you buy from us?

A: Geomembrane,Geogrid,Geocell, Geotextile, Geocomposite,

Q: Can I have a sample?

A: Yes. And sample free.

Q: What's the payment terms?

A: T/T or L/C. Others could be negotiated.

Q: What's the delivery time?

A: 3-20 days after confirming order, detail delivery date should be decided according to production season and order quantity.

Factory Appearance

RELATED PRODUCTS

GET A FREE QUOTE