High Tensile Strength PP Woven Geotextile for Soil Foundation lmprovement

Classification :

keyword:

Woven geotextile

PRODUCT DETAILS

| Product specification |

| Name; woven geotextiles |

| Thickness; 100g-800g |

| Length; 1-6 meters, if there is a unique measurement can be customized |

| Color; White, black, aid customized hues |

Woven geotextiles are a type of geosynthetic material that is commonly used in various civil engineering and construction projects. These geotextiles are made by weaving synthetic fibers together to create a strong and durable fabric that is designed to withstand various environmental conditions.

One of the main advantages of woven geotextiles is their high tensile strength, which allows them to provide effective reinforcement and stabilization for soil and other materials. This makes them ideal for use in applications such as road construction, embankment stabilization, and erosion control.

In addition to their strength, woven geotextiles also offer excellent filtration properties. This allows them to effectively separate different soil layers and prevent the mixing of fine particles, which can improve the overall performance and longevity of the structure.

Another key benefit of woven geotextiles is their durability. These materials are designed to withstand exposure to harsh environmental conditions, including UV radiation, chemicals, and moisture. This means that they can provide long-lasting protection and support for infrastructure projects.

Woven geotextiles are also versatile and easy to install. They can be easily cut and shaped to fit the specific requirements of a project, and can be quickly secured in place using various installation methods. This makes them a cost-effective and efficient solution for a wide range of geotechnical applications.

Overall, woven geotextiles play a crucial role in modern construction and engineering projects. Their combination of strength, filtration properties, durability, and versatility makes them a valuable asset for ensuring the success and longevity of various structures and infrastructure developments. Whether used for stabilizing slopes, reinforcing retaining walls, or preventing soil erosion, woven geotextiles are an essential component of any geotechnical engineering toolbox.

|

|

|

|

|

Woven geotextiles are a type of geosynthetic material that are commonly used in various civil engineering and construction projects. These geotextiles are made from polypropylene or polyester fibers that are woven together to create a strong and durable fabric.

One of the primary applications of woven geotextiles is in soil stabilization. When placed between layers of soil, these geotextiles help to prevent erosion and promote better soil compaction. This is particularly important in road construction, where the stability of the soil is crucial to the longevity of the road.

Woven geotextiles are also used in drainage applications. By allowing water to flow through the fabric while preventing the passage of soil particles, these geotextiles help to maintain the integrity of drainage systems and prevent clogging. This is especially useful in areas with high levels of rainfall or in agricultural applications where proper drainage is essential.

In addition, woven geotextiles are commonly used in the construction of retaining walls and embankments. By providing additional strength and stability to the soil, these geotextiles help to prevent slope failures and soil erosion. This is particularly important in areas with steep terrain or in areas prone to landslides.

Furthermore, woven geotextiles can also be used in landscaping and horticultural applications. By acting as a barrier against weeds and providing additional support to plants and trees, these geotextiles help to create a more stable and aesthetically pleasing environment.

Overall, the application scope of woven geotextiles is vast and diverse. From soil stabilization to drainage, retaining walls to landscaping, these geotextiles play a crucial role in the success of various construction and engineering projects. Their versatility, durability, and effectiveness make them an indispensable material in the field of civil engineering.

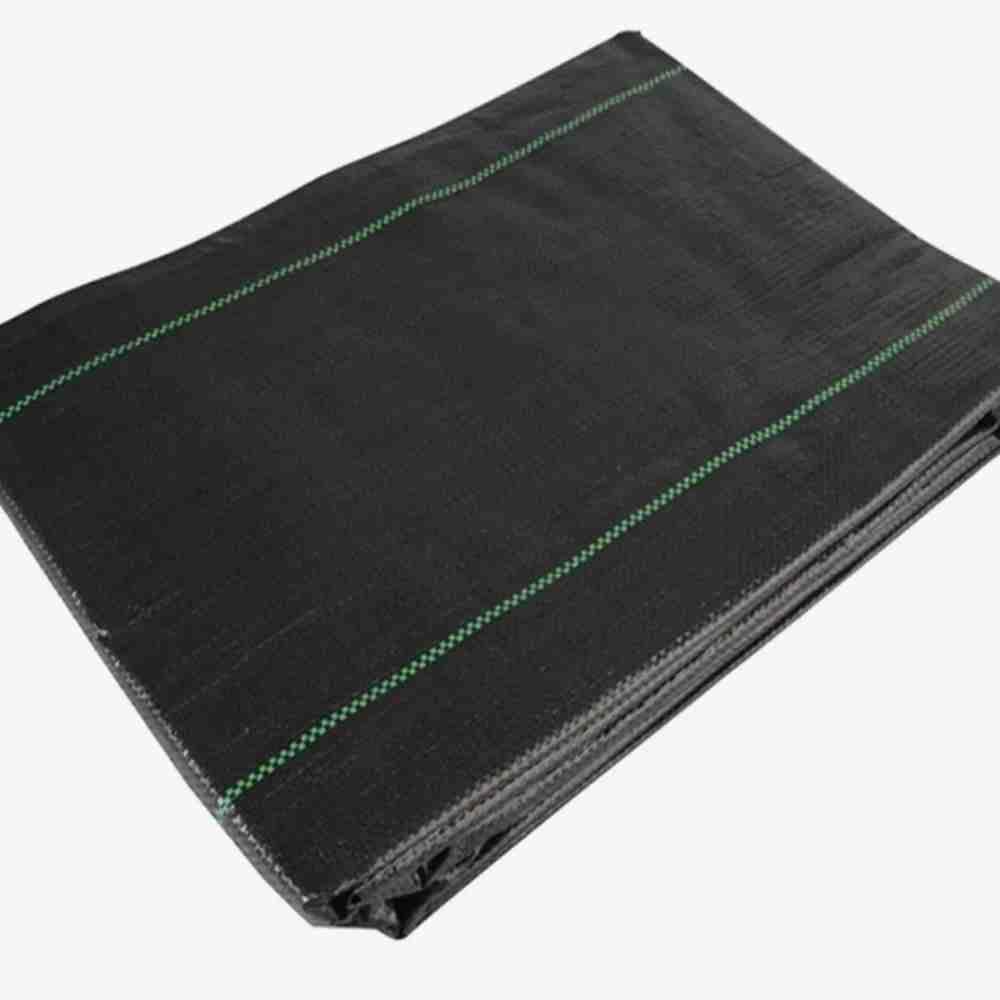

| project | unit | Testing standards | Technical parameters | ||||||||||||

| HK270 | HK370 | HK570 | HK380 /(a) | HK380B | HK580/(a) | HK580B | HK380PPi | HK380PPi-B | HK580PPi | HK580PPi-B | HKH2Oi | ||||

| Breaking strength | Meridian | KN/m | ISO 10319-2015 | 50 | 50 | 70 | 70 | 70 | 90 | 90 | 70 | 70 | 90 | 90 | 90 |

| zonal | 50 | 65 | 70 | 60 | 50 | 80 | 85 | 80 | 90 | 105 | 105 | 90 | |||

| Elongation at break | Meridian | % | ISO 10319-2015 | 10 | 10 | 10.5 | 10 | 10.5 | 10 | 10 | 13 | 13 | 14 | 14 | 13 |

| zonal | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 9 | 9 | 9 | 9 | 9 | |||

| Breaking strength at elongation 2% | Meridian | KN/m | ISO 10319-2015 | 13 | 13 | 15 | 15 | 15 | 18 | 18 | 10.5 | 9.5 | 8 | 7 | 9 |

| Breaking strength at elongation5% | Meridian | KN/m | ISO 10319-2015 | 30 | 30 | 38 | 38 | 38 | 45 | 45 | 30.6 | 25 | 22 | 25 | 28 |

| Mass per unit | g/m2 | GB/T13762-1992 | 225 | 250 | 310 | 280 | 260 | 375 | 380 | 340 | 345 | 420 | 435 | 430 | |

| Static breaking strength(CBR) | KN | GB/T 14800-2010 | 6 | 6.5 | 8 | 8 | 7 | 9 | 10 | 9 | 9 | 10 | 10 | 11 | |

| Equivalent aperture(O90) | mm | GB/T 14799-2005 | 0.42 | 0.45 | 0.48 | 0.48 | 0.33 | 0.45 | 0.4 | 0.48 | 0.48 | 0.47 | 0.48 | 0.45 | |

| permeability(Q50) | L/m2/s | GB/T 15789-2005 | 33 | 28 | 57 | 55 | 54 | 45 | 42 | 58 | 59 | 58 | 52 | 18 | |

| UV resistance(500 hour strong preservation rate) | % | ASTM D4355-2014 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | / | |

|

|

|

|

|

|

|

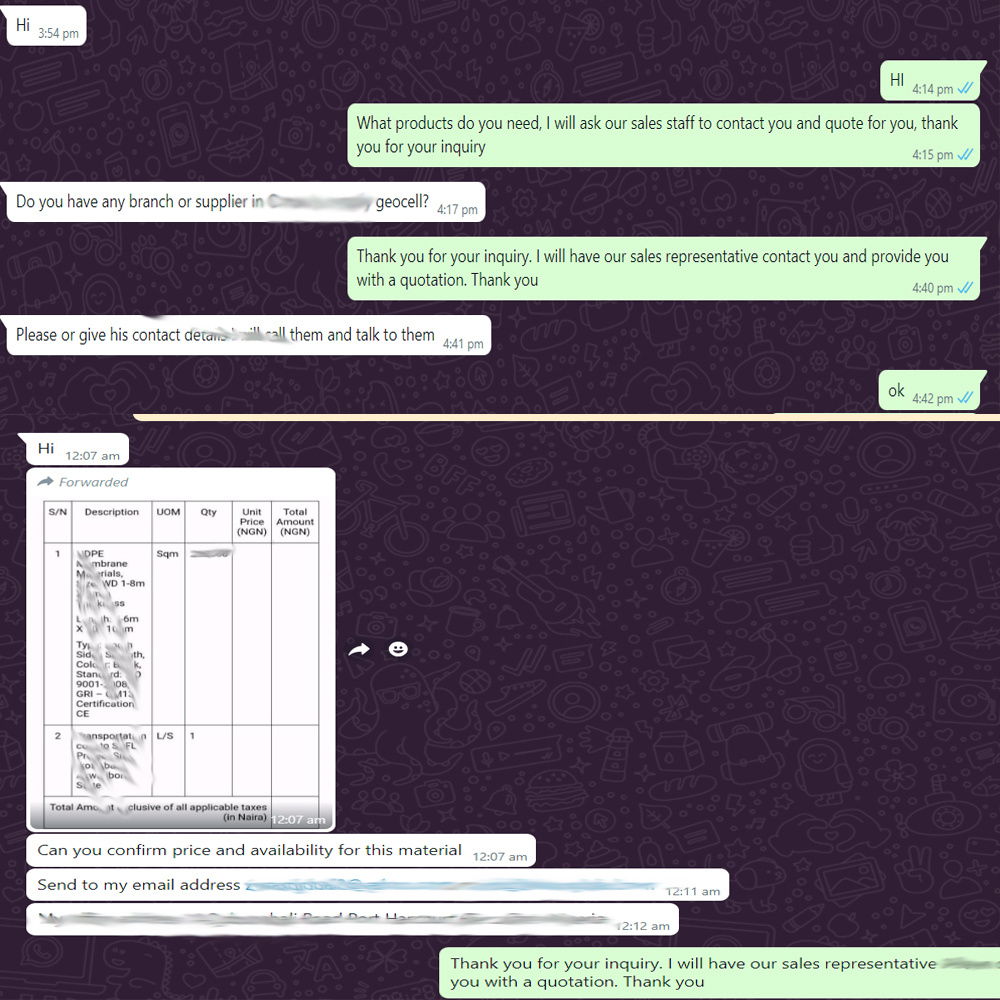

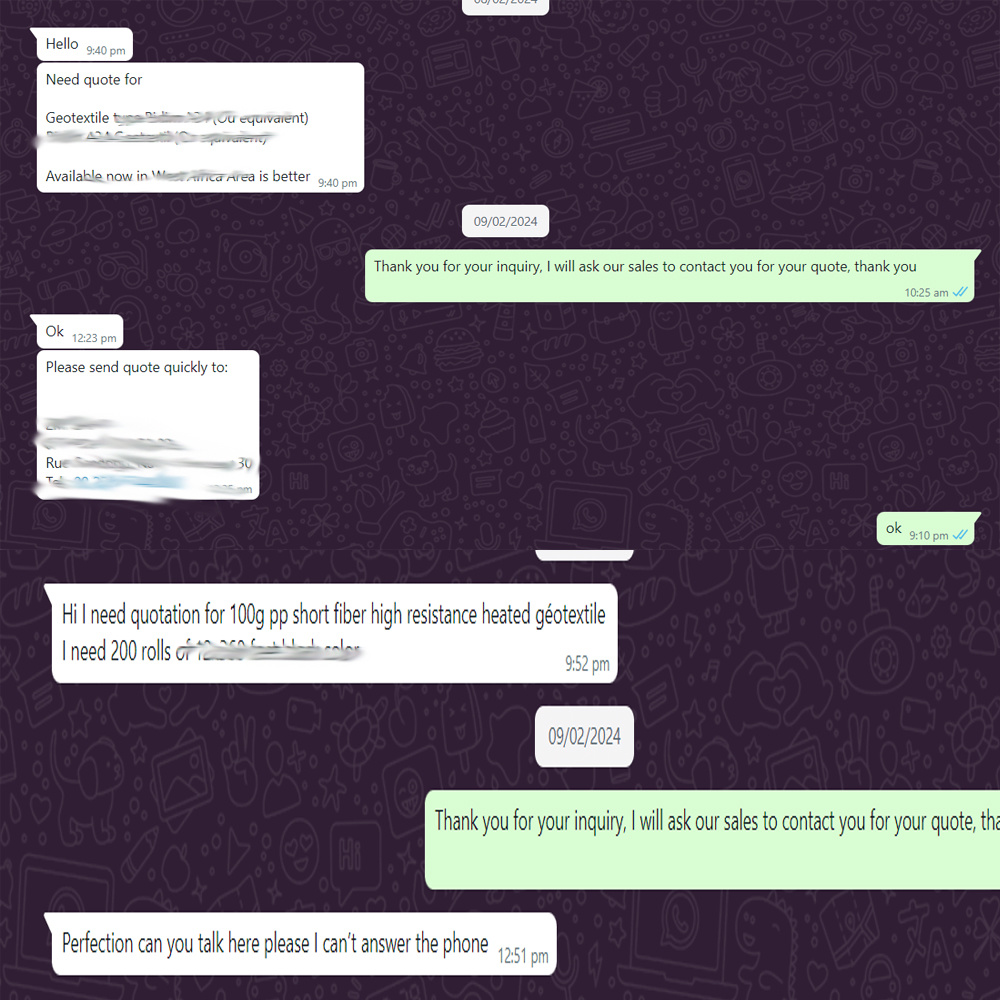

Q: What can you buy from us?

A: Geomembrane,Geogrid,Geocell, Geotextile, Geocomposite,

Q: Can I have a sample?

A: Yes. And sample free.

Q: What's the payment terms?

A: T/T or L/C. Others could be negotiated.

Q: What's the delivery time?

A: 3-20 days after confirming order, detail delivery date should be decided according to production season and order quantity.

Factory Appearance

RELATED PRODUCTS

GET A FREE QUOTE